Planted drying beds or planted dewatering beds are a specific treatment process for sewage sludge and are increasingly used to treat faecal sludge.

Sludge are dewatered and mineralized thanks to several mechanical, physical and biological processes.

Treatment mechanisms

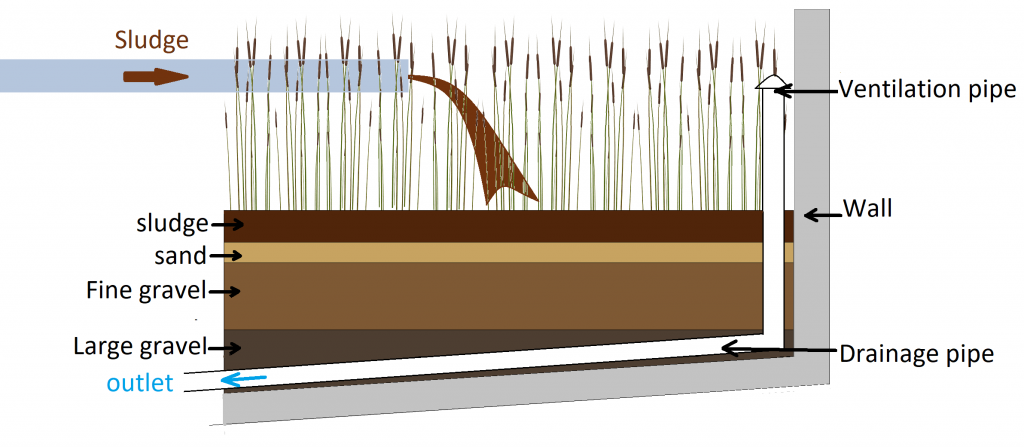

A planted drying bed is a filter bed of sand and gravels drained and planted with emergent macrophytes.

Filter bed consists of different layers of porus media with a grain size that increases in a downward direction. Faecal sludge are applied by batches on the bed surface where suspended solids are retained while liquid fraction percolates.

Local species of macrophytes with a very important root system had to be used. They need to be able to adapt to a complex environment.

Drying beds operate alternating feeding period and resting period to increase dewatering rate. That’s the reason why several dewatering beds had to be deployed in parallel.

Sludge dewatering

Sludge are dehydrated both by percolation through the filter and by evapotranspiration through plants.

Drainage

Sludge’s water trickles down through beds.

Perforated pipes situated at the bottom of the bed are used to drain filtrate. This mechanism helps to reduce and to dewater sludges. It happens during feeding period.

Evapotranspiration

Evapotranspiration combines two mechanisms: evaporation and transpiration. Evaporation occurs in the sludge surface. Transpiration is water movement through a plant and its evaporation from the leaf and stem surfaces. Plants absorb sludges moisture and release it via transpiration. All those phenomena happen during resting period.

Sludge mineralisation

Aerobic bacteria found in sludge and gravel pack mineralize organic matter contained in the sludge blanket. This mechanism contributes to sludge reduction and stabilization.

Design parameters

Principal operational parameters for a planted drying bed in tropical regions (EAWAG) to keep in mind while designing are:

- Loading: 60 to 250 kg TS/m2/year. Depending on the sludge source and conditions

- Feeding frequency: 1-3 times a week. Depending on the weather conditions, the dry matter content of the sludge and the plant species

- Resting: 2 days to several weeks. Depending on the weather conditions, the dry matter content of the sludge and the plant species

- Plant density: start-up with plant density of 4-12 shoots/m2

- Plant acclimatisation: start-up during a rainy or wet season is recommended. Apply domestic wastewater and gradually add FS until the plants achieve a height of 1 m.

- Plant harvesting: up to 3 times/year, following a few years of operations or during desludging. Depending on plant type, the growth status and valorisation option. Valid especially for Echinochloa pyramidalis.

Other operation parameters are also important to consider and that’s why an expert is needed to design this type of plant:

- Screening and grit removal might be needed depending on the sludge source and conditions

- The bed must be accessible by trucks that transport dried sludge

- Leachates coming from the drying beds need a specific treatment

Plants benefits

Macrophytes root system maintains sludge layer permeability. Sludge volume on the bed surface reduces continuously thanks to moisture loss through sludge layer porosity.Thus sludge can accumulate for several years before being cured and evacuated. This long accumulation period also helps their mineralization and pathogen reduction. Therefore, all the dewatered sludge can be immediately used in agricultural application.

Plants roots improve development of an aerobic environment helping. As a result, filtrate quality and sludge mineralization are significantly improved compared to a simple drying bed. A secondary treatment of filtrate may be necessary depending on their purpose.

Planted drying beds advantages

- Significant reduction of sludge volume by natural mineralization

- Sludge accumulate for several years

- ease and low cost of maintenance/operations

- low capital, operating, maintenance, supervision and energy costs (less than intensive and mechanical systems)

- No need of chemical flocculants

- limited impact on the environment (less than intensive and mechanical systems)

- no unpleasant smells

- pleasant esthetic

Planted drying beds disadvantages

- Hight site coverage

- Sludge removal need specific devices

- Starting up period can be long to respect progressive scaling period

- In case of malfunction, there may be unpleasant smells

- Need regular plant harvesting

Why using sludge planted drying beds?

Sludge planted drying beds can be used in these conditions:

- when site is large

- when agricultural application is possible

- when limited impact on the environment is needed

- when sludge volumes to treat are not important

To know if you can construct sludge planted drying beds, you need to take into account all your project. An expert may help you to see if your project is viable.

Maji Solutions can analyse your needs, conduct feasibility studies and design your sludge treatment plant. Feel free to contact us !

Read more:

Sanitation in sub-Saharan Africa

Legal notices: SuSanA Secretariat, CC BY 2.0

1 thought on “Planted drying beds: focus on a sludge treatment process”

Comments are closed.