Biogas plant has been used for decades to treat sewage sludge and increasingly used to treat faecal sludge. This process stabilizes, sanitizes and reduces sludge volume while producing a valuable biogas.

Treatment mechanisms

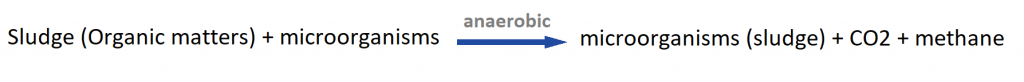

Methanization is the transformation of organic matter into biogas ( methane & carbon dioxide) by bacteria in anaerobic conditions (lack of oxygen).

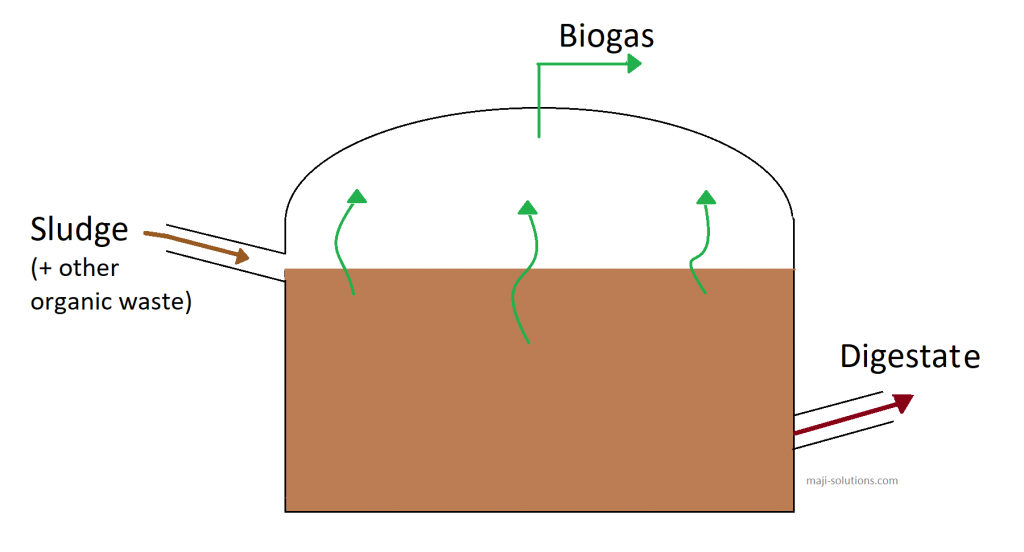

This degradation is only possible in the presence of fermentable materials: unstabilized sewage sludge, fresh faecal sludge and other organic waste such as manure, plants or food waste.

This anaerobic digestion occurs in an airtight reactor called “digester” . It is most often a cylindrical tank to facilitate homogenization.

In anaerobic conditions, organic matter is partially degraded by the action of several types of microorganisms. Since these bacteria are naturally present in faeces and sewage sludge, adding microorganisms is not needed.

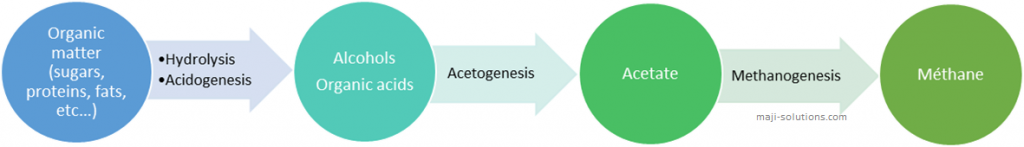

Several biological reactions are involved in biogas plant. There are three stages:

1. Hydrolysis and acidogenesis reactions: complex carbonaceous chains are converted into simpler compounds

2. Acetogenesis reaction: single carbonaceous chains are converted into acetic acid

3. Methanogenesis: acetic acid converted into methane and CO2

Biogas uses

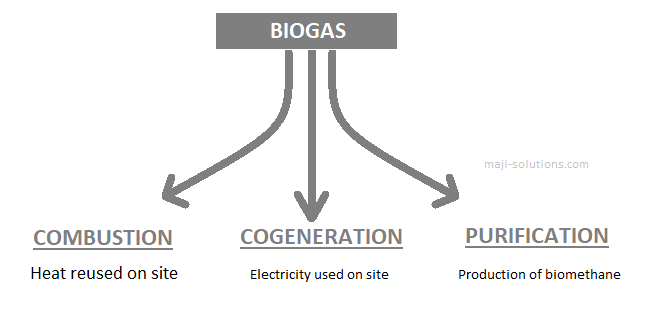

The main gaseous products of biogas plants are methane and carbon dioxide. Other minority gases can affect this biogas: H2S, water vapor and VOCs. Depending on this biogas final use, a treatment may be required.

There are different ways to use this biogas in African cities:

- Combustion: Biogas can be reused on site thanks to a gas boiler for sludge thermal drying.

- Cogeneration: biogas is converted in electricity used on site

- Purification: biogas is transformed into biomethane and then compressed for domestic or other use

The final biogas use is fundamental to design a profitable methanization plant. Sustainability and maintenance must be taken into account since the project beginning.

Biogas plant benefits

- Average reduction of sludge volume by 30-50%

- No olfactory nuisances

- Production of a stabilized, sanitized and fertilizing digestate

- Reduction of Volatile Organic Compounds

- Production of a valuable biogas (heat & electricity in situ, domestic gas)

- Creating local maintenance and operations jobs

Biogas plant disadvantages

- Large volumes of biogas have to be stored

- Biogas management may be expensive (purification, compression, etc.)

- Start-up can be long due to loading

- Sensitive to input quality

- Rigorous maintenance and monitoring to control parameters (pH & temperature)

- Any malfunction can be costly (stop, drain, restart)

Main Design parameters

1. The temperature of the process

Anaerobic digestion occurs in two temperature ranges:

- mesophilic range (35-40°C): most often implemented

- thermophilic range (55-60°C): allowing a greater reduction in sludge volume

2. Applied organic load and hydraulic retention time

These two parameters are related: for the same type of sludge increasing the load causes a decrease of the retention time. Depending on the biodegradability of the sludge, the overall retention time for sewage or faecal sludge is between 30 and 60 days.

Other design parameters

Other parameters should be taken into account to optimize the digestor plant performance and operation.

– The intensity of the reactor brewing. Efficient homogenization is necessary to reduce temperature differentials and the distribution of microorganisms in the reactor.

– Regular sludge input. Fresh sludge input and regular digestate extraction allow stable microorganisms development.

– Effective sludge pre-treatment. In the case of faecal sludge, a well-chosen pre-treatment makes organic matter more available for bacterial degradation.

Why using biogas plant?

Biogas plants can be used in these conditions:

- when sludge volumes to treat are important

- when there is a use for biogas

- when limited impact on the environment is needed

To know if you can construct biogas plants to treat your waste, you need to take into account all your project constraints. An expert may help you to see if your project is viable.

Maji Solutions can analyse your needs, design and construct biogas plant.

Read more: